|

|

|

| Crayford focuser | ||

|

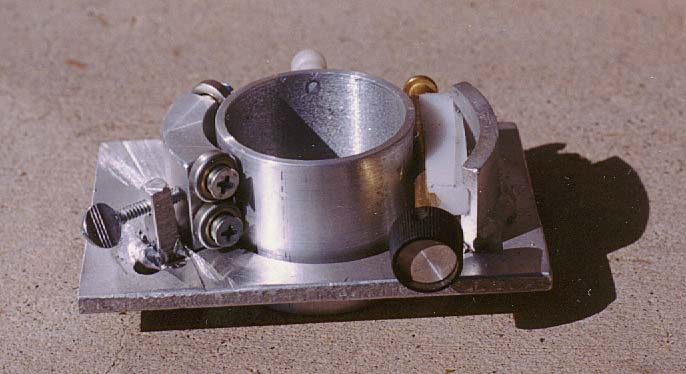

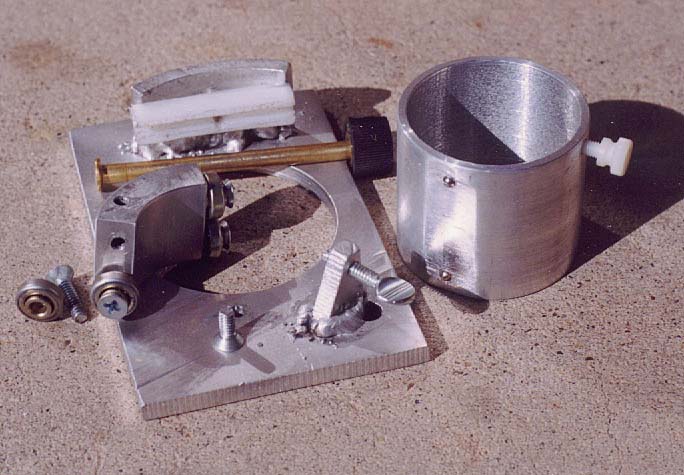

The Crayford style focuser shown here was built

using a lathe, bandsaw and MIG welding machine along with common power and

hand tools. I believe that with a bit more effort, a fine version could be

built using bolted construction with no welding and little or no

machining. Aluminum can be cut and smoothed well with hacksaw and files

though powered tools ease some of the tedious work.

The focus shaft is a standard door hinge pin. The bearings are from screen door rollers that have had the plastic removed. Router guide bearings would be great but are more expensive. I used a piece of UHMW plastic with a Vee-groove sawn in as a bearing support for the pin. The support for the ball bearings hinges on a small bolt that holds it to the base. The small bolt threads into a hole on one end of the support block and a thumb screw adjusts tension by pressure applied to the other end of the block. It can help compensate for load weights, wear and desired tension. This model has the bearings spaced close together to allow a short draw tube for a low profile focuser. The pin roller should have its height placed midway between the bearing axis for maximum stability but there is some leeway if eyepiece weight is not too heavy. I install these focusers on the tube such that the bearings are toward the bottom if possible so that the bearings support the weight instead of the hinge pin roller. Hopefully the photos are adequate to answer any questions the text fails to address. |